Overview

The ZW32-40.5 outdoor high-voltage vacuum circuit breaker adopts an integrated solid-sealed pole and a high-reliability operating mechanism. The device is mainly used in medium-voltage overhead line power grids for dividing and combining load currents, overload currents and short-circuit currents.

Main feature

a. High reliability

b. Maintenance free during the entire life c. High mechanical and electrical life

d. The whole machine is small in size, light in weight and easy to install

Normal use environment

◆Ambient air temperature: -30℃~ +60℃;

◆Altitude: no more than 3000m;

◆The wind speed does not exceed 34m/s;

◆Vibration or ground motion from outside the switchgear and control equipment is negligible;

◆Contamination level: Ⅳ level;

◆Storage temperature: -40℃~ +85℃.

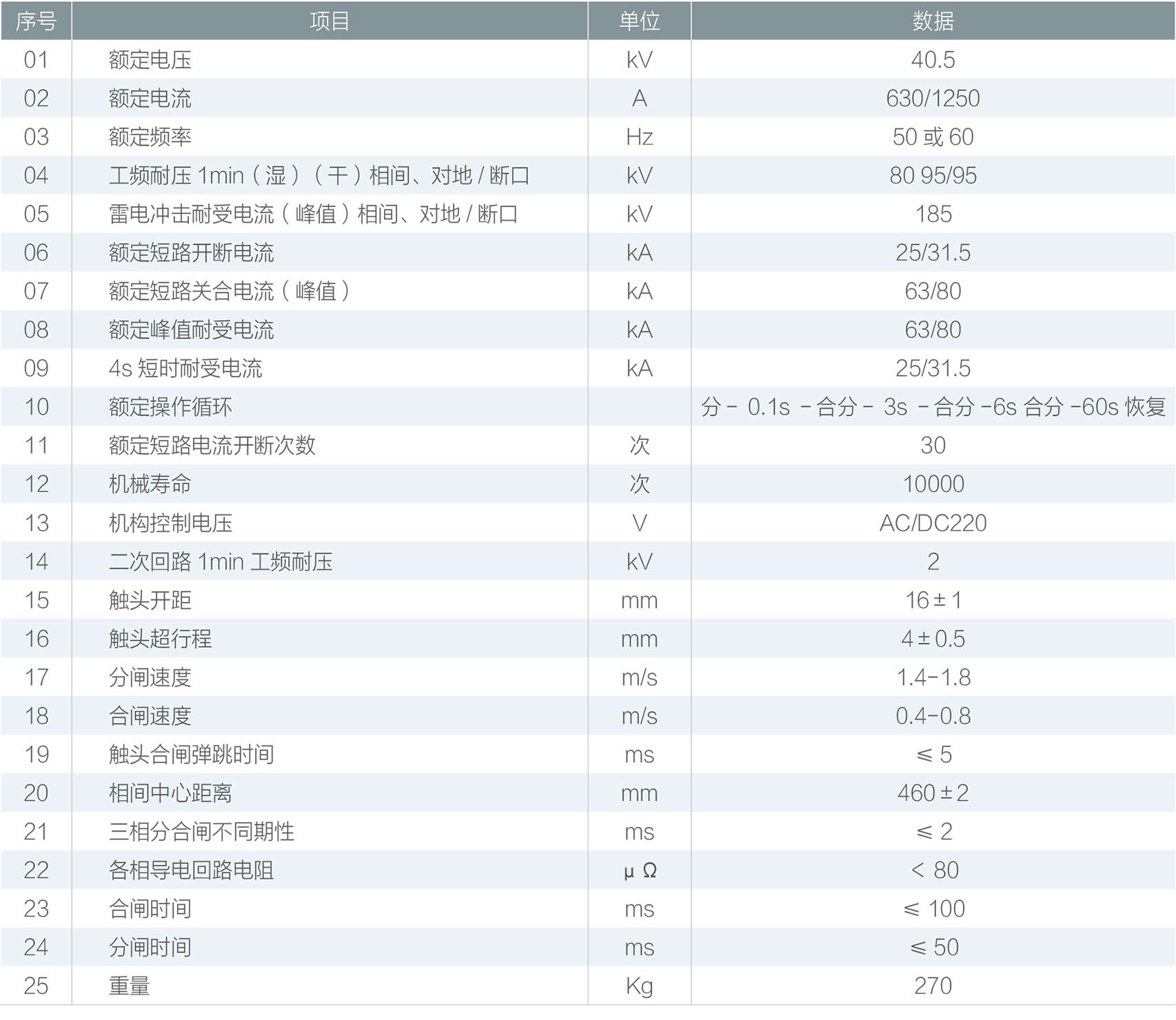

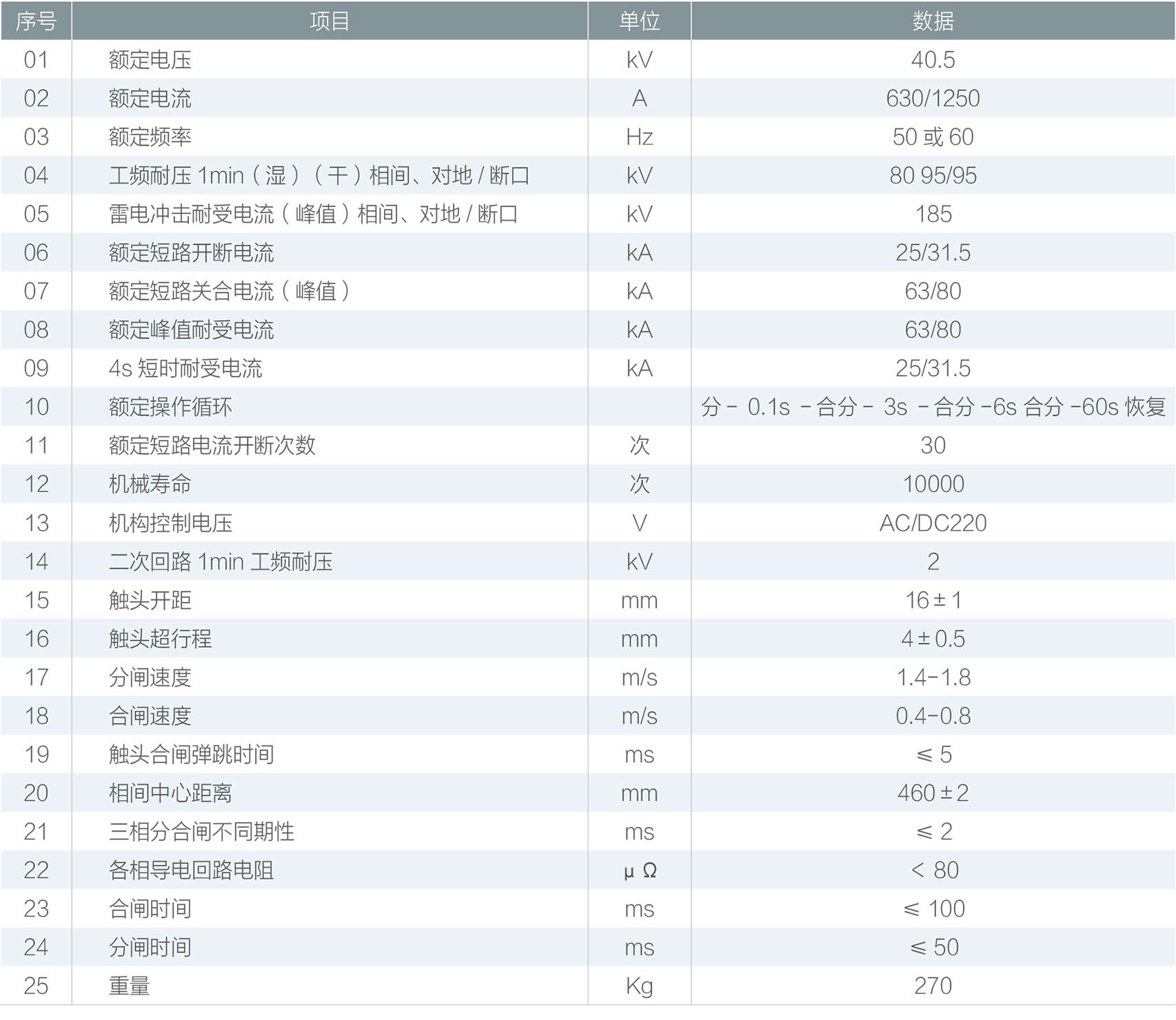

技术参数(见表)

Circuit breaker structure and working principle

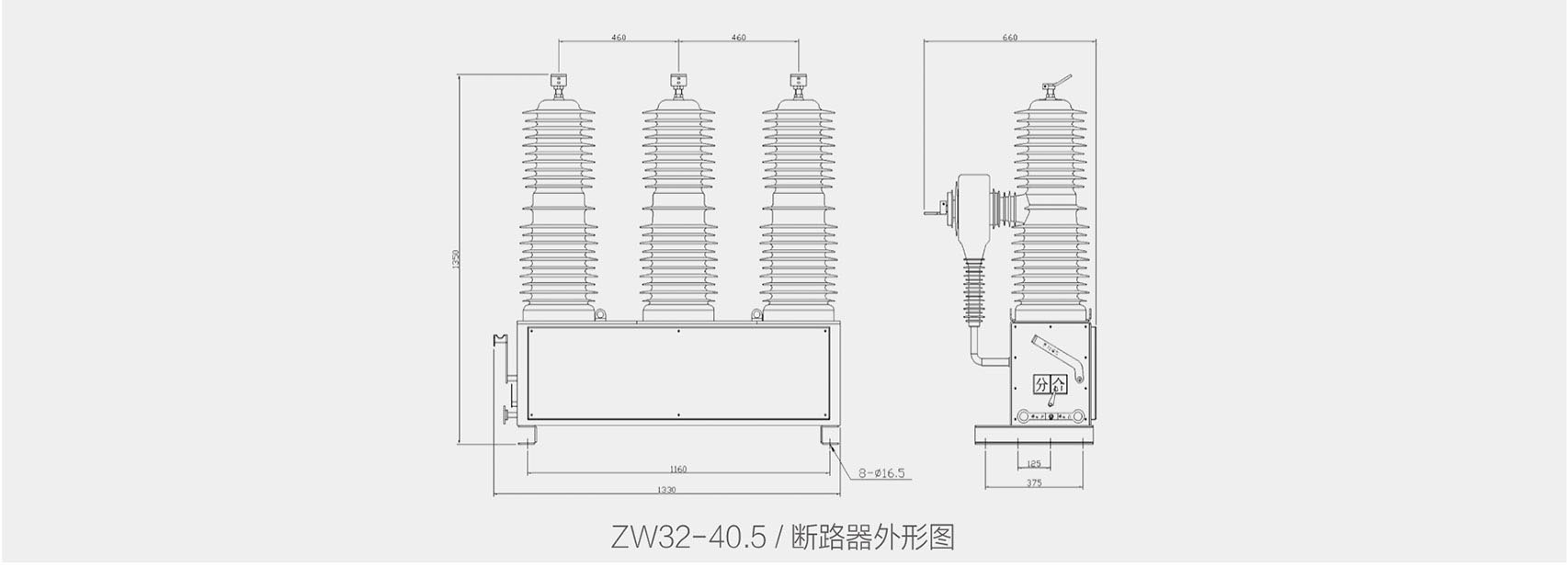

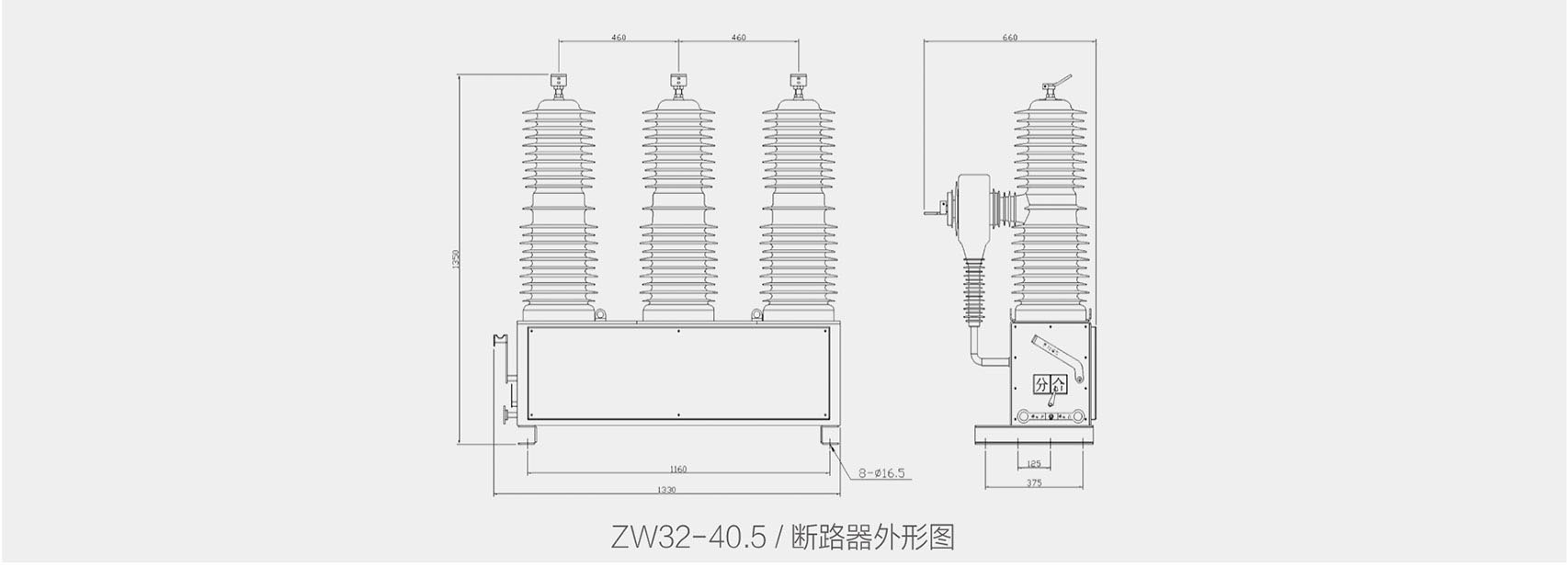

zW32-40.5 outdoor high-voltage vacuum circuit breaker is mainly composed of integrated solid-sealed pole, current transformer, operating mechanism and box. This type of circuit breaker is of miniaturized design, and the shell is made of high-quality steel box. Current transformers can be selected according to user needs.

ZW32- 4 0.5 outdoor high-voltage vacuum circuit breaker and matching intelligent control combination. The switch opening and closing operation can be realized locally, and it can also be remotely operated through the communication interface. Other information of the circuit breaker can also be transmitted to the control center, and the communication channel can choose cable, optical fiber, GPRS, ICDMA, GSM, etc.

How circuit breakers work

1. Arc extinguishing principle:

The zW32-40.5 outdoor high-voltage vacuum circuit breaker adopts a vacuum arc extinguishing chamber, which uses vacuum as the arc extinguishing and insulating medium, and has a high degree of vacuum. When the moving and static contacts are energized and opened under the action of the operating mechanism, a vacuum arc will be generated between the contacts. At the same time, due to the special structure of the contacts, an appropriate longitudinal magnetic field will also be generated in the gap between the contacts. Promote the vacuum arc to maintain a diffusion type, and make the arc evenly distributed on the surface of the contact to burn, maintain a low arc voltage, and when the current naturally crosses zero, the residual ions, electrons and metal vapors can be released in the order of microseconds. Composite or condensed on the contact surface and the shield, the dielectric strength of the arc extinguishing chamber fracture is quickly restored, so that the arc is extinguished to achieve the purpose of breaking. Because the longitudinal magnetic field is used to control the vacuum arc, the vacuum circuit breaker has a strong and stable breaking current capability.

2. Electric energy storage:

The motor acts on the pinion gear of the mechanism and transmits it to the large sprocket on the main shaft, thereby driving the crank arm to rotate, so that the closing spring can store energy. When the screw on the crank arm presses down the travel switch, the motor power is cut off, and the spring is charged.

3. Manual energy storage:

The output shaft of the rotating mechanism transmits the rotational torque to the large gear fully meshed with the pinion through the pinion on the output shaft, thereby driving the crank arm to rotate and making the closing spring store energy.

4. Closing solenoid operation:

After the mechanism receives the closing signal, the moving iron core of the closing electromagnet moves upward, and pushes the closing release lever to move upward, so that the closing half shaft rotates counterclockwise. Release the restraint on the closing latch, at the same time, the closing latch rotates counterclockwise under the pressure of the roller, releasing the energy storage maintenance, the cam located on the main shaft generates an impact force due to the contraction force of the closing spring, and hits the The rocker arm on the manual energy storage shaft (ie the output shaft) is transmitted to the switch through the connecting rod to complete the closing operation.

5. Manual operation:

When the shift fork installed on the closing half shaft rotates counterclockwise, it drives the closing half shaft to rotate in the counterclockwise direction. This produces the same effect as the closing electromagnet operation. 6. Reclosing operation:

After the mechanism releases the energy of the energy storage spring, the closing operation is completed. In the closed state, the mechanism performs the energy storage operation again. After the energy storage operation is completed, the mechanism is in the closed state and the energy storage state. In this state, once the correct signal is received , the mechanism can realize an automatic reclosing operation.

7. Opening solenoid operation:

After the mechanism receives the opening signal, the moving iron core of the opening electromagnet moves upward, and pushes the opening release lever to move upward, so that the opening half shaft rotates counterclockwise. Release the restraint on the opening brake. At the same time, the opening brake is pressed by the roller and rotates counterclockwise, and the rocker arm rotates counterclockwise due to the thrust of the opening spring in the switch, thereby completing the opening operation.

8. Manual operation:

When the fork installed on the opening half shaft rotates counterclockwise, it drives the opening half shaft to rotate in the counterclockwise direction, thus producing the same effect as the opening electromagnet. 9. Overcurrent tripping operation:

When the overcurrent coil in the overcurrent release passes the specified tripping current, the electromagnet acts and the push rod pushes the tripping rod. Rotate the opening half shaft counterclockwise to release the restraint on the opening latch to produce the same effect as the opening electromagnet operation, and complete the overcurrent tripping operation of the circuit breaker.